I. Why Customize a Pressure Sensor?

The pressure sensor is the core component of a pressure transmitter - it converts pressure signals into electrical or digital outputs, serving as the "heart" of the entire device.

For different application environments (such as high temperature, high pressure, corrosive media, or micro-pressure measurement), standard sensors often cannot fully meet system requirements.

In these cases, customized pressure sensors offer superior performance, dimensional compatibility, environmental adaptability, and optimized output interfaces - providing higher reliability and stronger competitiveness for your pressure transmitter.

II. Key Parameters to Confirm Before Customization

To help our engineering team design the right solution for you, please prepare the following core parameters before customization. These details directly affect the structural design, chip packaging, compensation method, and testing standards of the sensor.

1. Pressure Range

The pressure range determines the design of the sensing chip and diaphragm structure.

Required measurement range

Pressure type: Gauge, Absolute, or Differential

Accuracy requirements

2. Outer Diameter & Structure

The size and structure affect how the sensor integrates with your transmitter.

Sensor outer diameter, thickness, and installation space

Specific mounting interface requirements

3. Operating Temperature

Temperature conditions influence chip material selection, sealing materials, and temperature compensation design.

Medium and ambient temperature range

Any rapid temperature variations or thermal shocks

4. Measured Medium

The nature of the medium determines diaphragm and packaging material selection.

Type of medium (gas, liquid, oil, steam, etc.)

Whether the medium is corrosive, prone to scaling, contains particles, or is volatile

Material compatibility requirements

5. Output Signal

The output type must be compatible with your transmitter's circuit system.

Desired output: mV signal, UART digital signal, I²C, or others

Need for amplification, temperature compensation, or digital calibration

6. Wiring Method

Proper wiring ensures signal stability and reliable assembly.

Wire lead or Kovar pin connection

Cable length, shielding, and waterproofing requirements

7. Performance Parameters

These parameters define the sensor's quality and consistency.

Linearity, hysteresis, and repeatability requirements

Limits on temperature coefficients (TCO, TCS)

8. Supply Voltage

Supply voltage affects output amplitude and internal circuit design.

System voltage range (e.g., 5V DC, 10V DC)

Multi-voltage compatibility if needed

9. Temperature Compensation

Temperature compensation improves measurement stability, especially for precision transmitters.

Required accuracy over the full temperature range

Need for factory calibration and full-range temperature compensation

10. Quantity

Quantity information helps optimize tooling, production time, and cost.

Sample quantity and mass production requirements

Future plans for volume manufacturing

III. Our Technical Support After Receiving Your Parameters

Once we receive your detailed parameters, our engineering team will provide:

Technical evaluation and selection advice: Based on pressure range, temperature, and medium conditions.

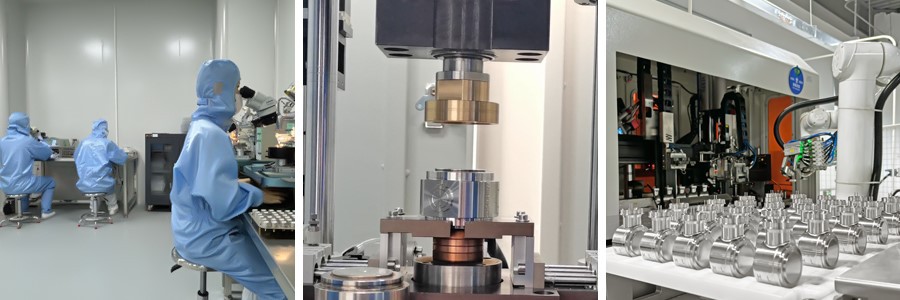

Structural and material design: Recommended diaphragm materials, sealing methods, and packaging structures.

Output circuit and compensation design: Matching circuits and temperature compensation for mV or UART outputs.

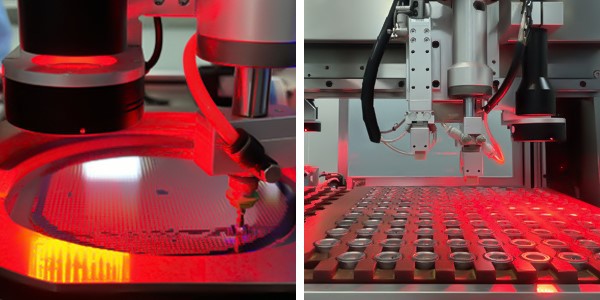

Sample development and testing: Prototype fabrication with full temperature cycling and pressure fatigue tests.

Mass production and quality traceability: Factory calibration data and consistency reports included with bulk shipments.

IV. Customization Process Overview

Provide complete customization parameters.

Our engineers conduct technical evaluation and confirm feasibility.

We offer a solution proposal and sample quotation.

Upon approval, samples are produced and performance tested.

After sample validation, mass production begins with continuous technical support.

V. Summary

Customizing a pressure sensor is not only about meeting special requirements - it's about achieving higher sensitivity, stability, and competitiveness for your pressure transmitter.

By simply providing the key parameters, our engineering team will design the most suitable sensing solution for your application - from design to mass production, we offer comprehensive technical support at every stage.